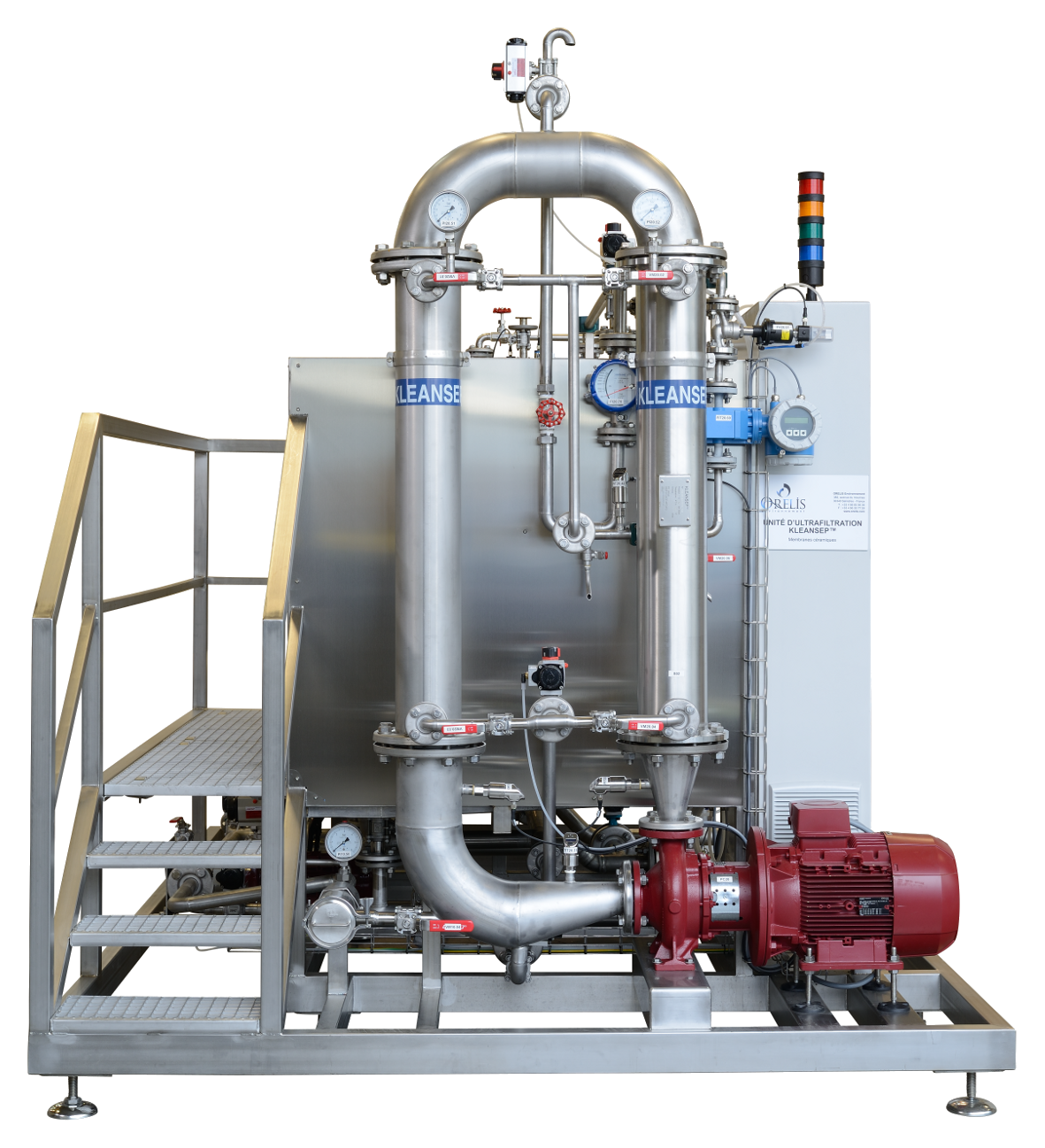

Fabrication and assembly of the system

Knowledge and experience

- 400 membrane systems installed during more than 30 years, and in 20 countries, including the USA, France, Germany, Spain, China, Canada and Australia

- A team of process, mechanical, electrical/automation engineers, and industrial designers

- Proven Quality Assurance for O&G, Nuclear, Chemical, Water, Marine, Food, Bio-industries, Fine Chemicals (biotechnology, cosmetics, pharmaceuticals)

- Typical skid frame materials including coated carbon steel, stainless steel, and plastic

- Assembly of membranes in modules

- Project management expertise from $ 50,000 to $5 million

- 10 different standard systems

Data sheets (.pdf):

- ALSYS – EN0030 – KLEARSEP OILY WATER SEPARATOR – Data Sheet – V03.21

- ALSYS – EN0082 – PERSEP ULTRAFILTRATION SYSTEM – Data Sheet – V02.21

- ALSYS – EN0020 – KLEANSEP ULTRAFILTRATION SYSTEM – Case study Degreasing Baths – V05.21-2

- ALSYS – US0601 – CeraMem Primary Metal Industry – Case study – V07.19.pdf

- ALSYS – US0602 – CERAMEM CERAMIC MEMBRANES AND MODULES – Data Sheet – V03.21

Objectives

- Procedural controls include Quality documents (List of Manufacturing and Control Operations, List of Assembly and Control Operations, Executed Work File…)

- Qualification and purchase of equipment, instruments and specialized services

- Wiring and electrical cabinets

- PLC programming (Schneider, Siemens, Alan Bradley)

- Module assembly and leak test

- Use and maintenance instructions manual

- Compliance with ATEX, ESP, 3-A sanitary, nuclear, ISO standards…

Recent activities:

- Membrane filtration systems for water and valuable resource recovery from wine and beverage production wastes (tubular polymeric reverse osmosis membranes)

- Unit for nuclear industry (ceramic membrane)